What is Six Sigma?

Six Sigma is a business management strategy, originally developed by Motorola, that today enjoys wide-spread application in many sectors of industry.

Six Sigma seeks to identify and remove the causes of defects and errors in manufacturing and business processes. It uses a set of quality management methods, including statistical methods, and creates a special infrastructure of people within the organization (“Black Belts” etc.) who are experts in these methods. Each Six Sigma project carried out within an organization follows a defined sequence of steps and has quantified financial targets (cost reduction or profit increase).

Historical overview

Six Sigma was originally developed as a set of practices designed to improve manufacturing processes and eliminate defects, but its application was subsequently extended to other types of business processes as well.[2] In Six Sigma, a defect is defined as anything that could lead to customer dissatisfaction.[1]

The particulars of the methodology were first formulated by Bill Smith at Motorola in 1986.[3] Six Sigma was heavily inspired by six preceding decades of quality improvement methodologies such as quality control, TQM, and Zero Defects, based on the work of pioneers such as Shewhart, Deming, Juran, Ishikawa, Taguchi and others.

Like its predecessors, Six Sigma asserts that –

- Continuous efforts to achieve stable and predictable process results (i.e. reduce process variation) are of vital importance to business success.

- Manufacturing and business processes have characteristics that can be measured, analyzed, improved and controlled.

- Achieving sustained quality improvement requires commitment from the entire organization, particularly from top-level management.

Features that set Six Sigma apart from previous quality improvement initiatives include –

- A clear focus on achieving measurable and quantifiable financial returns from any Six Sigma project.[1]

- An increased emphasis on strong and passionate management leadership and support.[1]

- A special infrastructure of “Champions,” “Master Black Belts,” “Black Belts,” etc. to lead and implement the Six Sigma approach.[1]

- A clear commitment to making decisions on the basis of verifiable data, rather than assumptions and guesswork.[1]

Six Sigma is a registered service mark and trademark of Motorola, Inc.[6] Motorola has reported over US$17 billion in savings[7] from Six Sigma as of 2006.

Other early adopters of Six Sigma who achieved well-publicized success include Honeywell International (previously known as Allied Signal) and General Electric, where the method was introduced by Jack Welch.[8] By the late 1990s, about two-thirds of the Fortune 500 organizations had begun Six Sigma initiatives with the aim of reducing costs and improving quality.[9]

In recent years, Six Sigma has sometimes been combined with lean manufacturing to yield a methodology named Lean Six Sigma.

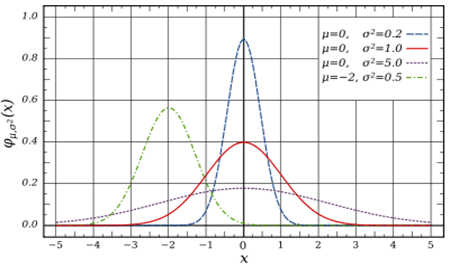

Graph of the normal distribution, which underlies the statistical assumptions of the Six Sigma model. The Greek letter σ marks the distance on the horizontal axis between the mean, µ, and the curve’s point of inflection. The greater this distance is, the greater is the spread of values encountered. For the curve shown in red above, µ = 0 and σ = 1. The other curves illustrate different values of µ and σ.

Origin and meaning of the term “six sigma process”

The following outlines the statistical background of the term Six Sigma.

Sigma (the lower-case Greek letter σ) is used to represent the standard deviation (a measure of variation) of a statistical population. The term “six sigma process” comes from the notion that if one has six standard deviations between the mean of a process and the nearest specification limit, there will be practically no items that fail to meet the specifications.[5] This is based on the calculation method employed in a process capability study.

In a capability study, the number of standard deviations between the process mean and the nearest specification limit is given in sigma units. As process standard deviation goes up, or the mean of the process moves away from the center of the tolerance, fewer standard deviations will fit between the mean and the nearest specification limit, decreasing the sigma number.[5]

The role of the 1.5 sigma shift

Experience has shown that in the long term, processes usually do not perform as well as they do in the short.[5] As a result, the number of sigmas that will fit between the process mean and the nearest specification limit is likely to drop over time, compared to an initial short-term study.[5] To account for this real-life increase in process variation over time, an empirically-based 1.5 sigma shift is introduced into the calculation.[10][5] According to this idea, a process that fits six sigmas between the process mean and the nearest specification limit in a short-term study will in the long term only fit 4.5 sigmas – either because the process mean will move over time, or because the long-term standard deviation of the process will be greater than that observed in the short term, or both.[5]

Sigma levels

Taking the 1.5 sigma shift into account, short-term sigma levels correspond to the following long-term DPMO values (one-sided):

- One Sigma = 690,000 DPMO = 31% efficiency

- Two Sigma = 308,000 DPMO = 69.2% efficiency

- Three Sigma = 66,800 DPMO = 93.32% efficiency

- Four Sigma = 6,210 DPMO = 99.379% efficiency

- Five Sigma = 230 DPMO = 99.977% efficiency

- Six Sigma = 3.4 DPMO = 99.9997% efficiency

Methodology

Six Sigma has two key methodologies: [9] DMAIC and DMADV, both inspired by Deming‘s Plan-Do-Check-Act Cycle. DMAIC is used to improve an existing business process; DMADV is used to create new product or process designs.[9]

DMAIC

The basic methodology consists of the following five steps:

- Define process improvement goals that are consistent with customer demands and the enterprise strategy.

- Measure key aspects of the current process and collect relevant data.

- Analyze the data to verify cause-and-effect relationships. Determine what the relationships are, and attempt to ensure that all factors have been considered.

- Improve or optimize the process based upon data analysis using techniques like Design of Experiments.

- Control to ensure that any deviations from target are corrected before they result in defects. Set up pilot runs to establish process capability, move on to production, set up control mechanisms and continuously monitor the process.

DMADV

The basic methodology consists of the following five steps:

- Define design goals that are consistent with customer demands and the enterprise strategy.

- Measure and identify CTQs (characteristics that are Critical To Quality), product capabilities, production process capability, and risks.

- Analyze to develop and design alternatives, create a high-level design and evaluate design capability to select the best design.

- Design details, optimize the design, and plan for design verification. This phase may require simulations.

- Verify the design, set up pilot runs, implement the production process and hand it over to the process owners.

DMADV is also known as DFSS, an abbreviation of “Design For Six Sigma”.[9]

Implementation roles

One of the key innovations of this is the professionalizing of quality management functions. Prior to Six Sigma, quality management in practice was largely relegated to the production floor and to statisticians in a separate quality department. Six Sigma borrows martial arts ranking terminology to define a hierarchy (and career path) that cuts across all business functions and a promotion path straight into the executive suite.

Six Sigma identifies several key roles for its successful implementation.[12]

- Executive Leadership includes the CEO and other members of top management. They are responsible for setting up a vision for Six Sigma implementation. They also empower the other role holders with the freedom and resources to explore new ideas for breakthrough improvements.

- Champions are responsible for this implementation across the organization in an integrated manner. The Executive Leadership draws them from upper management. Champions also act as mentors to Black Belts.

- Master Black Belts, identified by champions, act as in-house coaches on this . They devote 100% of their time to this . They assist champions and guide Black Belts and Green Belts. Apart from statistical tasks, their time is spent on ensuring consistent application of this across various functions and departments.

- Black Belts operate under Master Black Belts to apply this methodology to specific projects. They devote 100% of their time to Six Sigma. They primarily focus on Six Sigma project execution, whereas Champions and Master Black Belts focus on identifying projects/functions for this .

- Green Belts are the employees who take up this implementation along with their other job responsibilities. They operate under the guidance of Black Belts.

Quality management tools and methodologies used in Six Sigma

Six Sigma makes use of a great number of established quality management methods that are also used outside of Six Sigma. The following table shows an overview of the main methods used.

- 5 Whys

- Analysis of variance

- ANOVA Gage R&R

- Axiomatic design

- Apollo Root Cause Analysis ARCA

- Business process mapping

- Catapult exercise on variability

- Cause & effects diagram (also known as fishbone or Ishikawa diagram)

- Chi-square test of independence and fits

- Control chart

- Correlation

- Cost-benefit analysis

- CTQ tree

- Customer survey through use of Enterprise Feedback Management (EFM) systems

- Design of experiments

- Failure mode and effects analysis

- General linear model

- Histograms

- Homogeneity of variance

- Pareto chart

- Pick chart

- Process capability

- Regression analysis

- Run charts

- SIPOC analysis (Suppliers, Inputs, Process, Outputs, Customers)

- Stratification

- Taguchi methods

- Thought process map

- TRIZ

Software used for Six Sigma

Analysis tools

- IBM WebSphere Business Modeler

- JMP

- Microsoft Visio

- Minitab

- SigmaXL

- Statgraphics

- STATISTICA

- Telelogic System Architect

- Actuate

List of Six Sigma companies

The following companies claim to have successfully implemented Six Sigma in some form or another:

- 3M[1]

- Advanced Micro Devices[2]

- Agilent Technologies

- Air Canada

- Amazon.com[3]

- AXA

- Bank of America[4]

- Bechtel Corporation[5]

- Boeing[6]

- Canada Post

- Caterpillar Inc.[7]

- CIGNA

- Cognizant Technology Solutions

- Computer Sciences Corporation[8]

- Cummins Inc.

- Deere & Company[9]

- Dell[10]

- DHL

- Dominion Resources

- DSB Bank

- DuPont

- EMC

- Flextronics

- Ford Motor Company[11]

- General Electric[10]

- General Dynamics

- Genpact

- Honeywell[12]

- Ingram Micro

- Korea Telecom

- Kraton Polymers

- KTF

- LG Group

- Littlewoods Shop Direct Group[13]

- Lockheed Martin[14]

- Mando Corporation

- McKesson Corporation[15]

- Merrill Lynch

- Microflex, Inc.

- Motorola[10]

- Mumbai‘s Dabbawala[16]

- National Australia Group Europe

- Network Rail

- Nortel Networks

- Northrop Grumman[10]

- Patheon

- Precision Castparts Corp.

- QMS management consultants, repsented six sigma in malaysia.[http://www.qms-mal.com

- Quest Diagnostics, Inc

- Raytheon[10]

- Samsung Group

- SGL Group

- Shinhan Bank

- Shinhan Card

- Siemens AG

- SKF

- Vodafone

- Starwood Hotels & Resorts Worldwide[17]

- Sterlite Optical Technologies

- Teradyne

- Trane

- Textron

- United States Air Force[18]

- United States Army[19]

- United States Marine Corps[20]

- United States Navy[21]

- UnitedHealth Group

- Wipro