Better Project Management Performance with Six Sigma

Every organization faces the daunting task of executing projects that meet or exceed the expectations of its customers. That makes project management a key component of most enterprises, regardless of the business sector. Yet project management is not always met with organization-wide satisfaction. Inevitably many PMO processes are little more than copies of what other companies have implemented. They lack a root-level connection to the company they support.

Better Project Management Performance with Six Sigma

PMO Designed to Meet Customer Needs

When a project is not properly planned, the PMO may be forced to improve systems never designed to meet the customer’s needs, and subsequently appear to fail to meet those needs. The root cause of this failure arises from the disconnection between process performance metrics and customer needs.

To maximize a project’s performance, management needs to build a better project management process dedicated to meeting the customer’s most important needs.

Better Project Management Performance with Six Sigma

DMEDI Step 0: PMO Charter

The PMO charter should answer all of the following key questions:

- Sponsor/Champion

- Who will be where the buck stops? The project Sponsor/Champion must hold a position high enough in the organization to enforce the plans defined for the PMO.

- Business impact

- What are the quantifiable desired gains from the PMO?

- What stands gained when from a successful PMO?

- Opportunity or problem

- What is the current quantifiable deficiency that has caused the need for a PMO?

- Goal statement

- What should the PMO look like and produce?

- What will the data say to provide a picture of success?

- PMO scope

- What should the PMO be doing and not be doing?

- Where should and should not the PMO operate?

- Project plan

- How long and when will the PMO operate?

- What are the key milestones in its development and measurement?

- PMO team

- Who are the players on this project?

- Who will manage the daily activities?

- Who will participate in establishing the PMO?

Better Project Management Performance with Six Sigma

DMEDI Step 1: Define

In order to maximize individual project performance, the company’s senior leadership must first establish and agree upon what the overall objective is for the PMO. This objective must fall in line with the overall company’s and customer’s objectives.

This task is significant and many organizations still struggle with it. Operational definitions which need clear definition include:

Better Project Management Performance with Six Sigma

- Project must be defined and scoped:

- Who is authorized to initiate a project?

- What is required to initiate a project?

- What is the breadth and scope of the project?

- What is the project engagement process?

- Customer must be defined and stratified into clear categories:

- Internal (finance, sales, service, delivery, etc.)

- External (new customers, existing customers, vendors)

- Financial benefit must be clearly defined, according to the following elements:

- Direct external (i.e., new business, new customers, etc.)

- Direct internal (i.e., reduction in production costs)

- Indirect (i.e., losses or costs avoided)

- Currency (gross or net profit to the organization)

Finally, the chief financial officer (CFO) or chief operating officer (COO) must regularly assess PMO performance. The CFO/COO should monitor how the quality of execution has met the strategic vision and overall business needs. Without this high-level oversight, the PMO may come to serve an internal department as opposed to the overall business.

DMEDI Step 2: Measure

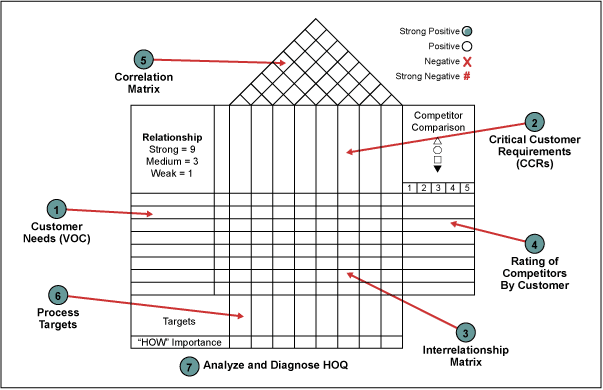

The secret in the definition of metrics is that customers value services differently. This is where the QFD tool pays off. This tool quantifiably identifies the priorities of the customer’s needs. The QFD tool helps develop the services a PMO will need to satisfy the customer’s needs. Once the services are identified, metrics can be developed to measure them. Properly developed metrics will be closely tied to PMO services that are:

- Essential to the customer’s core needs: Services and metrics must address needs important to the customer and not the company.

- Quantifiable: A company cannot show excellence if it cannot measure what it has done.

- Comprehendible: The PMO services will not be utilized if customers do not understand them.

1. Customer needs (VOC)

– For each critical customer segment, capture customer feedback and VOC input consisting of customer “needs.”

– Prioritize each need on a scale from 1 to 9.

2. Critical customer requirements (CCRs)

– The top row of the house contains the CCRs.

– How will meeting measures customer requirements?

– Translate customer’s terms into process or feature terms.

– Identify ways to deliver on customer needs.

3. Interrelationship matrix

– Evaluate relationships between customer needs (what’s) and critical customer requirements (how’s).

– Determine relative importance of each critical customer requirement.

4. Customer rating of competitors

– Who is the competition?

– How do customers perceive the competition’s ability to meet the requirements?

– What do competitors do that the company’s customers value?

5. Correlation matrix

– Compare CCRs (hows) to identify conflict, influence or no effect on each other.

6. Process targets

– Determine minimum and desired performance specifications for each CCR.

7. Analyze and diagnose

– Evaluate the house of quality process.

DMEDI Step 3: Explore

The Explore phase seeks to discover the most efficient and best way for the PMO to meet or exceed the customer’s needs. While still at a high level, the company can recognize the opportunity for great innovation. The objective is to identify innovative ways to provide what the customer’s need.

Remember to ensure that all of the functions in the PMO model are measurable. Therefore this is the perfect time to build a system to measure the PMO’s services. This system must measure each project key metrics and aggregate their sums.

DMEDI Step 4: DevelopKeep the core PMO deliverables in focus and make sure the team does not omit any of the following:

- Human resources and staffing plan

- Who will work the PMO?

- How many will work in each role?

- What will they be paid?

- Facilities plan

- Where will the PMO be located?

- What physical resources will be needed?

- Supplies and materials plan

- What will the PMO need to operate?

- What will it cost to set the office up?

- What will it cost for the PMO to operate?

- Technology plan

- What hardware and software will be needed for the PMO?

- What IT services will be needed?

- How will the PMO fit into the company’s business continuity/disaster recovery plans?

DMEDI Step 5: Implement or Re-launch

When the PMO model has been developed or improved, it is time to implement a pilot of the new process. Select a reasonably achievable, moderate-risk project and process it through the new model. The measurement tools should evaluate how the pilot project met or missed the service objectives established in the Measure step. Any necessary changes should be made to ensure future projects will meet the defined customer requirements.

Conclusion: DMEDI Is a Logical Course

The Lean Six Sigma methodology will benefit efforts with its implementation and process control discipline. Without this initial investment in the quality of design for the PMO, the company may see the initiative fall apart after its initial launch.

Ultimately a Design for Lean Six Sigma deployment is the most logical course for any organization seeking to develop a strong PMO or resurrect an ailing one. The DMEDI roadmap can guide any company through the development process and help reduce or eliminate unwanted complexity. Proper use will infuse the PMO with customer-oriented services that satisfy the customer’s most important needs.

About the Author: Steven H. Jones is a process engineer who earned his certification as a Lean Six Sigma Black Belt while employed at Xerox Global Services. His career began with the 3M Corporation, an early adopter of the Lean Six Sigma methodology, and he has worked in quality improvement of telecommunications and IT arenas since 1993. Since then, he has provided quality improvement and process engineering services to customers in North America and Europe, including Baxter Healthcare, BP Canada, Convergys and Microsoft. He is currently a senior process engineer with Siemens Business Services.